-

JAKA Zu 18 Collaborative Robot

About JAKA Zu 18

The JAKA Zu 18 is a collaborative robot with the largest payload in the jAKA Zu range – 18kg – with a significant working radius – 1073mm.

It can utilize this ability for standard heavy-lifting tasks, but also for delicate, accurate tasks; its 6-axis configuration endows it an outstanding repeatability of ±0.03 mm.

Despite its large payload, the Zu 18 is incredibly safe. It features visual and torque-feedback collision protection systems that allow is to operate in any environment, without he need for a safety fence.

JAKA Zu 18 is perfect for use in myriad tasks: packaging, palletizing, welding, testing, screw tightening, mold injection, bonding and more.

It is used across industries such as the production or testing of medical devices, metal processing, chemical manufacture, as well as standard manufacturing and warehousing.

-

JAKA Zu 12 Collaborative Robot

Meet the JAKA Zu 12, our smart, dynamic, mid-size collaborative robot built for industrial automation.

About JAKA Zu 12

The JAKA Zu 12 handles payload – 12kg – and larger working radius – 1327mm – than the previous models in the JAKA Zu range. It can complete manual tasks that would take at least two people to do, and can do so for 50,000 hours non-stop.

Thanks to its 6-axis configuration, the JAKA Zu 12 is reliable and accurate, with an outstanding repeatability of ±0.03 mm.

For such a high payload, it is relatively light, and can be mounted at any angle – vertical, horizontal, and anything in between.

The flexibility, safety and reliability combined make it perfect for work in the automotive and auto parts industry, advanced manufacturing, household appliances industry, for food packaging and much more.

-

JAKA Zu 7 Collaborative Robot

Push output and value higher, on production lines and in factories, with this easy to teach, and easy to operate JAKA Zu 7.

About JAKA Zu 7

Spending hours working with weights of up to 7kg is exhausting to any person. With a payload of 7kg, JAKA Zu 7 can do so for 50,000 hours non-stop, at a working radius of 819mm!

Repetitive tasks, such as welding, packaging, palletizing, picking and placing and more are no problem, freeing up people to perform the less physically intensive tasks required in a smart factory. It can do so mounted at any angle – on a horizontal surface, a vertical surface, on a slope or hanging from above.

Most of our JAKA Zu 7 customers come from the automotive, 3C electronics, advanced manufacturing, renewable energy, medical devices, chemical & synthetic fibers industries, but this cobot is suitable for many other industries too.

-

JAKA Zu 5 Collaborative Robot

With a payload of 5kg, and a working radius of 954mm, the Jaka Zu 5 cobot is perfectly suited for repetitive operations such as picking and placing, welding, assembly and more.

Its features are fine-tuned for use in 3C electronics, automotive and other industries that require high levels of accuracy.

The JAKA Zu’z 5 visual and collision protection systems ensure that they can operate in harsh and unpredictable environments, with no need for a safety fence.

Compact size and flexible mount options make it easy to place at any angle – vertically, horizontally, on a slope or even on the ceiling, upside-down.

-

JAKA Zu 3 Collaborative Robot

The JAKA Zu 3 presents cutting-edge human-robot collaboration. Through drag and graphic programming, it is easy to teach and use the cobot. In-built torque feedback ensures safety, no matter how much of the 3kg payload is used, across its working radius of 626mm.

It’s perfect for screwdriving, electronic assembly, small surface pick and place, and other line and maintenance tasks. Its mounting options allow it go anywhere – fixed on a slant, upside-down, or even vertically.

Its compact size, together with full functionality, makes it suitable for 3C electronics and advanced manufacturing.

-

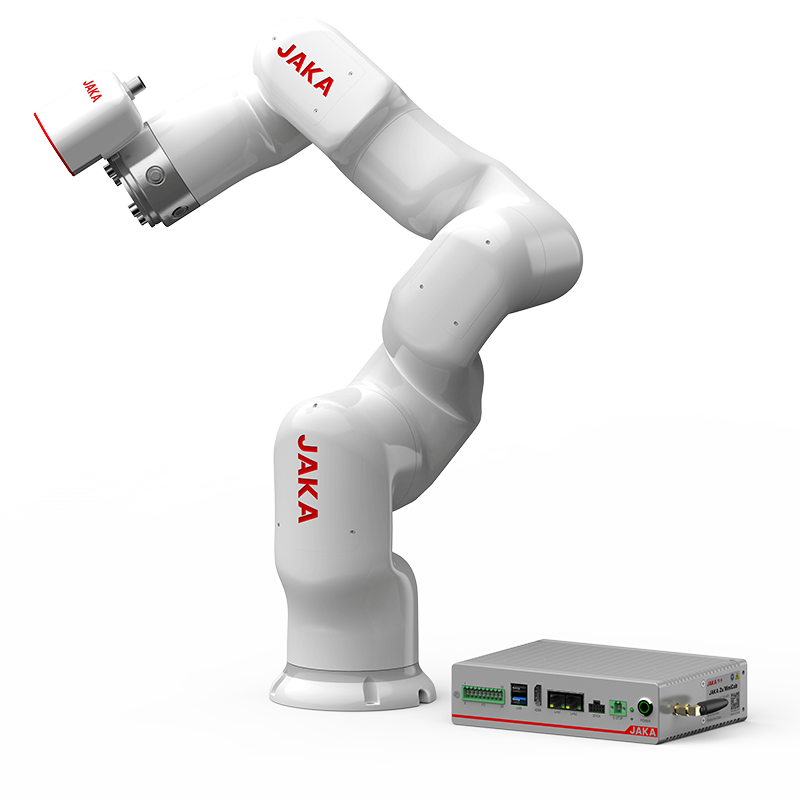

JAKA MiniCobo

About JAKA MiniCobo

JAKA MiniCobo has the characteristics of lightness, compactness, high flexibility, and easy installation.

It uses an integrated intelligent drive module to achieve a lightweight design while having superior performance; in addition, rich secondary development interfaces provide customers with more choices in different scenarios.

JAKA MiniCobo has a small appearance, simple and intuitive operation, low noise, and high-cost performance. It is especially suitable for consumption, service, education and other fields.